Call our product expert : +8615327455845

Email Us

Introduction

In industrial environments, undetected leaks in compressed air systems, steam traps, or electrical equipment can lead to massive energy waste, safety hazards, and costly downtime. Traditional leak detection methods—like soap-bubble tests or handheld ultrasonic detectors—are time-consuming and often impractical for large-scale inspections.

The Fluke ii905 and ii915 Industrial Imaging Acoustic Imagers are cutting-edge tools that combine ultrasonic sensing with visual imaging to transform how maintenance teams identify and diagnose leaks. In this article, we’ll explore their key features, real-world applications, and why they’re becoming indispensable for modern industrial maintenance.

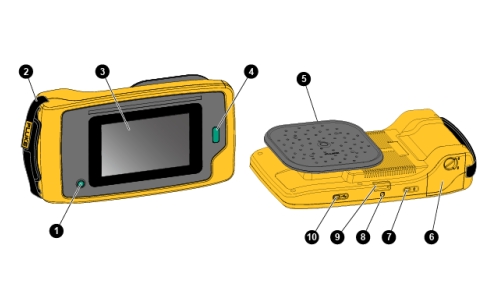

| Button | Function | Button | Function |

| 1 | Power On/Of | 6 | Battery Compartment |

| 2 | Hand Strap | 7 | USB-C Connector for charging |

| 3 | Touchscreen Display | 8 | Tripod Connection |

| 4 | Capture Button for Image or Start/Stop Video | 9 | Neck Strap Anchor |

| 5 | Acoustic Sensor | 10 | USB-C Connector for data communication |

Key Features of the Fluke ii905/915

1. Advanced Acoustic Imaging Technology

- Equipped with 64 high-sensitivity microphones, the ii905/915 detects ultrasonic frequencies (20–100 kHz) and overlays sound anomalies onto a real-time visual image (via a built-in 5MP camera).

- SoundSight Technology visually highlights leaks, allowing users to pinpoint exact locations without guesswork.

2. Rugged and User-Friendly Design

- IP54-rated for harsh industrial environments.

- Features a 7-inch touchscreen with an intuitive interface for on-site analysis.

- 5-hour battery life ensures extended field use.

3. Multiple Detection Modes

- Leak Mode: Measures leak severity in dBµV, helping prioritize repairs.

- Corona/Discharge Mode: Identifies dangerous electrical arcing in high-voltage systems.

- Data Logging: Capture images/videos with sound metadata for reporting and analysis.

4. Portability and Efficiency

- Weighing just 1.5 kg (3.3 lbs), it’s far more efficient than traditional methods, scanning large areas in minutes.

Practical Applications

Compressed Air Leak Detection

A single 3mm leak in a compressed air line can cost $1,000+ annually in wasted energy. The ii905/915 quickly locates leaks, enabling fast repairs.

HVAC & Refrigeration Systems

Detect refrigerant leaks or faulty ductwork with visual confirmation, reducing system downtime.

Electrical Inspections

Safely identify corona discharge and partial discharge in switchgear, transformers, and insulators—critical for preventing failures.

Steam Trap & Valve Audits

Auditing steam systems manually is labor-intensive. The ii905/915 scans multiple traps simultaneously, flagging inefficient ones.

Why It’s Better

- Faster – Scan entire systems in minutes.

- More Accurate – Visual + dBµV data eliminates false positives.

- Safer – Inspect electrical systems from a distance.

Best Practices for Optimal Use

1. Distance Matters – For best results, maintain 1–10 meters from the target (adjust for leak size).

2. Minimize Background Noise – Avoid using near loud machinery.

3. Use SoundSight Cloud – Upload data for deeper analysis and reporting.

Conclusion

The Fluke ii905 and ii915 Acoustic Imagers are game-changers for industrial maintenance, offering speed, precision, and safety in leak detection. By converting ultrasonic sounds into visual data, they empower teams to cut energy waste, prevent failures, and optimize operations.