Call our product expert : +8615327455845

Email Us

Bakersfield, CA – October 12, 2016 – ProSoft Technology, a leader in industrial communication solutions, is proud to announce the release of the ILX69-PBS, a PROFIBUS Slave Communication Module designed for Rockwell Automation’s CompactLogix™ and MicroLogix™ platforms. This innovative module enables seamless integration of PROFIBUS DP networks with Allen-Bradley PLCs, providing robust and flexible connectivity for industrial automation applications.

Key Features of the ILX69-PBS

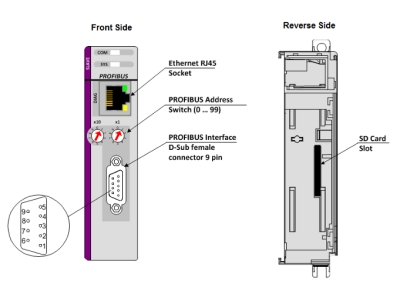

Figure: ILX69-PBS module front (left) and rear (right) views, highlighting PROFIBUS and Ethernet interfaces.

PROFIBUS DPV1 Slave Support: Facilitates high-speed cyclic and acyclic data exchange with PROFIBUS DP masters, ensuring reliable communication in demanding environments.

CompactLogix™ Compatibility: Easily integrates into 1769 backplane systems, supporting controllers like the 1769-L23, 1769-L32E, and 1769-L36ERM.

Flexible Configuration: Configurable via master software (using GSD file PSFT0EE1.GSD) or directly through the CompactLogix™ PLC program for enhanced control.

Dual Communication Interfaces:

PROFIBUS Interface: Supports baud rates from 9.6 kBit/s to 12 MBit/s with auto-detection.

Ethernet Diagnostics: Features an RJ45 port for web-based diagnostics, firmware updates, and real-time monitoring.

Removable SD Card: Enables firmware updates and configuration backups, ensuring quick recovery and maintenance.

Robust Safety and Compliance: Certified for use in Class I, Division 2 hazardous locations and meets UL 508 standards.

Applications

The ILX69-PBS is ideal for industries requiring seamless PROFIBUS integration with Rockwell Automation controllers, including:

Manufacturing automation

Process control systems

Material handling

Energy and utilities

Technical Highlights

Power Supply: 5V from the backplane (570 mA max).

Isolation: 500V galvanic isolation for both PROFIBUS and Ethernet interfaces.

Environmental Resilience: Operates in temperatures from 0°C to 60°C and withstands harsh industrial conditions.

Ease of Use

The module includes user-friendly tools such as:

Web-based diagnostics for real-time status monitoring.

LED indicators for communication (COM), system status (SYS), and Ethernet activity (LINK/ACT).

Studio 5000/RSLogix 5000 support, including Add-On Profiles (AOP) for simplified configuration.

For more details, visit ProSoft Technology’s website or contact their support team.